|

Getting your Trinity Audio player ready...

|

NASA is working to build a research base on the moon to send the first astronauts to Mars. Along the way, a new industry is coming to life: construction on surfaces beyond Earth. This is where master’s student Brandon Aguiar ’21 is launching his promising career.

Aguiar is advancing a 3D printing technique that makes durable structures out of lunar dust. He has produced igloos, building blocks and cubes with complex angles and curvatures.

Essentially, Aguiar is researching a material that could be the backbone of interstellar engineering.

“It’s very expensive to ship supplies to space. One pound of material can cost thousands of dollars,” says Aguiar, a life-long fan of space exploration. “Just imagine what it would cost taxpayers to ship entire houses to the moon. Instead, we can use the material that is already there to build infrastructure.”

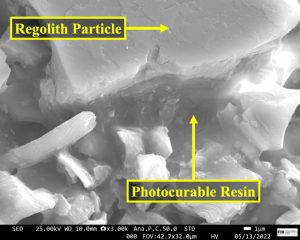

Lunar dust is a powder consisting of tiny, irregularly shaped rocks. It covers the moon and can present a potential hazard for astronauts. In previous missions, the dust has eroded spacesuits and sensitive equipment.

Aguiar’s research would flip this hazard into an asset. Using a lunar dust simulant provided by NASA, he is working with a material that has approximately five times the hardness of mild steel. Now, the College of Engineering and Computing student is focusing on how to make his 3D-printed objects withstand all the perils of the moon, including radiation, asteroids and temperature swings.

Aguiar works under the guidance of engineering experts at FIU’s Plasma Forming Laboratory. One of those experts is Ambreen Nisar, a research assistant professor who researches ceramic materials used for space exploration and hypersonic vehicles.

“On Earth, temperatures are very different depending on where you go. The weather in Miami is super hot, but somewhere in the northwest, it’s still freezing. The same happens when you are on the moon,” Nisar said. “Any material that is used needs to withstand extreme thermal shock.”

Aguiar joins other researchers around the country who are focused on making structures out of lunar dust. In particular, Aguiar is focused on finding a way to manufacture the structures to withstand the harshest elements of space. The key is getting the parameters of the 3D printing and treament process right. He mixes the dust with a resin, which is likea glue, to bind the small rocks together. Then, he 3D prints the material and puts it through a furnace to acquire the desired shape and to burn away the resin.

It’s like cooking, Aguiar says; the ingredients and parameters must be exactly right. He learned it from Professor Arvind Agarwal, director of the Plasma Forming Laboratory.

“When I’m teaching my new students, I always use the example of cooking to explain materials engineering,” Agarwal says. “You can make a chicken into either grilled chicken or fried chicken. The taste is completely different, but the starting material is the same. The same goes for lunar dust used in Brandon’s research. By modifying how he ‘cooks’ the dust, he can completely change how his structures perform.”

Aguiar will continue his research on a Presidential Fellowship as a Ph.D. student at FIU this fall. His 3D-printing method and parameters are pending patents and were recently published in a journal.

Aguiar’s research is a continuation of a senior project done by FIU Ph.D. student Kazue Orikasa, who is now researching how plastics could be used to protect technology in space.